The manufacturing overhead rate is derived from the most recent history of factory overhead costs actually incurred, perhaps for the past year or (more accurately) for the past three months on a rolling basis. These overhead costs are then divided by an estimate of the average number of units expected to be produced in the forecast period to arrive at the manufacturing overhead rate. This amount is loaded into the bill of materials for each product that a business manufactures, so how to find manufacturing overhead rate that the standard rate is automatically assigned to each unit as it is produced. It is often difficult to assess precisely the amount of overhead costs that should be attributed to each production process. Costs must thus be estimated based on an overhead rate for each cost driver or activity.

- It allows overhead to be assigned to production based on activity (DLHs), providing insight into profitability across products.

- Knowing how to calculate these costs can help manufacturers make informed decisions about their operating budget and prioritize investments that will positively impact their bottom line.

- This involves a thorough review of past expenditures and a careful projection of future indirect costs, ensuring that all factory-related expenses, from utilities to indirect labor, are accounted for.

- Furthermore, exercising control over the overhead costs of production is essential to effectively regulate the total cost of production.

- This approach can disconnect production costing from the technology resources actually consumed during manufacturing.

- This rate is then used throughout the period and adjusted at year-end if necessary based on actual overhead costs incurred.

Related AccountingTools Courses

For example, if direct labor hours are the chosen base, the company estimates the total direct labor hours expected for the year. This estimation, like that of total overhead costs, relies on historical data, production forecasts, and operational plans. These estimations of costs and activity levels form the foundation for an accurate overhead rate calculation. How to Invoice as a Freelancer Manufacturing overhead comprises various indirect costs essential for factory operations. These costs generally fall into categories such as indirect materials, indirect labor, and other manufacturing costs. Each category includes expenses that support the production process without being directly integrated into the final product.

Activity-Based Costing (ABC)

Monthly depreciation expense must be included in overhead as in indirect cost. However, if your company’s manufacturing overhead rate is low, it means that your manufacturing process is efficient. On the other hand, if your overhead rate is greater, your manufacturing process is defective. Let’s see the five types of manufacturing overhead which are related to indirect costs. In a word, the semi-variable overhead costs are that they are both variable and fixed. Finally, always remember that overhead is a relative term; it is essential to compare actual overhead costs against targeted levels to effectively utilize the company’s resources.

- If manufacturing a dining table requires 5 direct labor hours, the overhead cost allocated to each table would be $100.

- Similarly, in industries in which production is seasonal, the period selected should be longer as compared to that in which production volume does not fluctuate from period to period.

- If the variance is significant and has arisen from an error in the fixation of rates, production costs should be adjusted.

- To find manufacturing overhead, you simply need to identify any costs that don’t relate to the direct manufacture of a product and add them together.

- If you can’t tie the cost directly to one product being built, there’s a good chance it belongs in the overhead category.

- Indirect materials are supplies used in the production environment that do not become a physical part of the finished good or are too insignificant to track per unit.

- Let us understand the concept of a fixed and allocated manufacturing overhead formula with the help of a few examples.

Physical Costs – Manufacturing Overhead

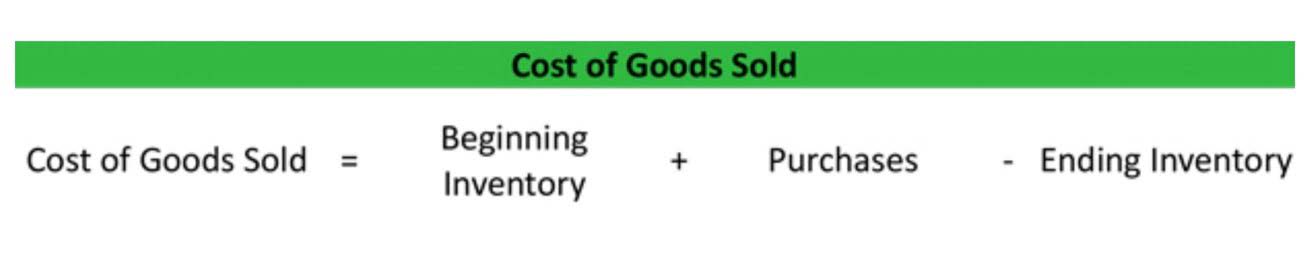

This is why it’s important to review and adjust your overhead calculations regularly. Businesses handle under- or overapplied overhead at the end of the accounting period. A common approach is to adjust the Cost https://compraenlospedroches.com/calculating-cost-of-goods-sold-with-the-fifo/ of Goods Sold account for the entire amount.

Negotiate with vendors – Reduce Manufacturing Overhead

Usually, actual capacity fluctuates from year to year and may be more or less than the normal capacity. Budgeted capacity represents the expected (planned) level of activity for the budget period. Practical capacity is determined by deducting unavoidable operating interruptions from theoretical capacity, and is usually expressed as a percentage of theoretical capacity. On an average, practical capacity is expected to be between 75% and 85% of the theoretical capacity.

It is crucial to keep track of these expenditures and account for them appropriately in the manufacturing process. For example, overhead costs may be applied at a set rate based on the number of machine hours or labor hours required for the product. In order to know the manufacturing overhead cost to make one unit, divide the total manufacturing overhead by the number of units produced. Enter the total cost of goods sold, cost of raw materials, and direct labor costs. Manufacturing overhead, also known as factory overhead or manufacturing support costs, is the indirect cost of the production process.

Understand how to calculate these indirect costs precisely to unlock the key to effective pricing strategies and maximize your bottom line. A fixed manufacturing overhead formula helps a manufacturing unit maximize efficiency in its production process as this process is its primary revenue source. It also allows them to use and reuse materials at their fullest potential and routine maintenance checks are encouraged to ensure machines are in pristine condition to keep the production plan on track. As manufacturing environments continue to evolve with increased automation, digital transformation, and changing production methodologies, so too will approaches to overhead calculation and management. Forward-thinking manufacturers should view overhead management as an ongoing journey of refinement rather than a fixed accounting procedure.

Manage manufacturing costs with Cin7

Because these costs are spread across multiple products, they require a bit more effort to allocate accurately. All of the different types of manufacturing overheads must be taken into account when calculating the total manufacturing overhead cost. However, the direct manufacturing costs include all the costs to produce a product perfectly such as the raw materials costs, labor costs, variable and semi-variable costs, etc.

How do you calculate predetermined overhead rate in accounting?

This actionable intelligence helps manufacturers target process improvements precisely where they will have the greatest impact on overhead cost reduction. Enterprise Resource Planning (ERP) systems have revolutionized the management of manufacturing overhead costs by integrating various operational functions into a unified data ecosystem. These systems excel at connecting financial data with operational metrics, allowing manufacturers to correlate overhead expenses with specific production activities, departments, or product lines.